Triangular roof trusses are a marvel of structural engineering, combining geometric efficiency with material innovation to support diverse loads. Their weight-bearing capacity depends on a synergy of design principles, materials, and environmental factors. Here’s a breakdown of the science, modern advancements, and real-world applications, including insights from Harbin Dongan Building Sheets Co., Ltd. and international case studies.

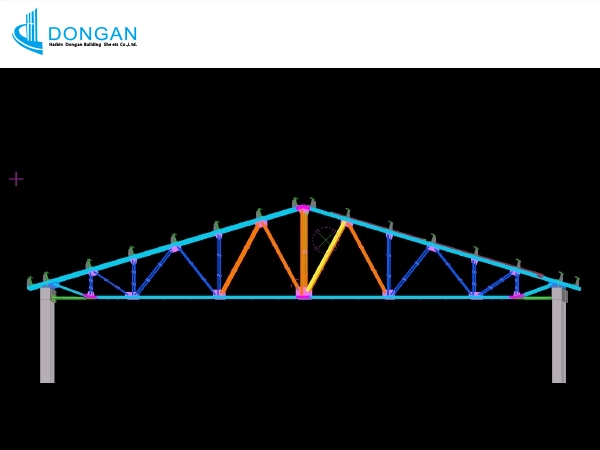

1. The Engineering Principles of Triangular Trusses

The inherent stability of triangles stems from their ability to distribute forces evenly. When vertical loads (e.g., snow, equipment) act on a triangular truss, compressive and tensile stresses are channeled through:

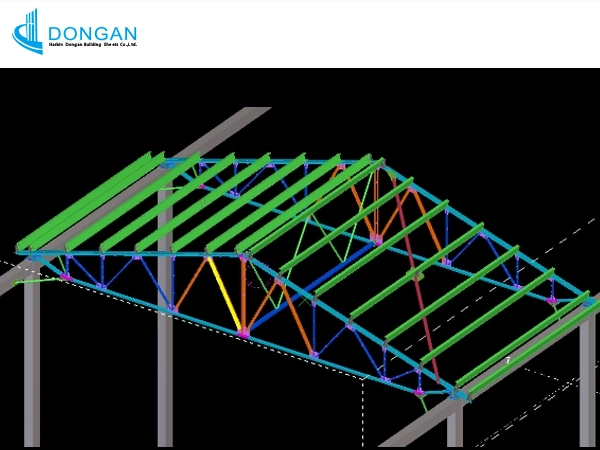

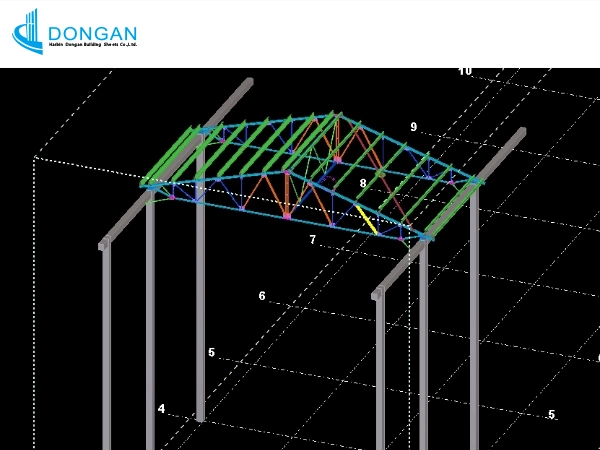

- Top chords (compression members),

- Bottom chords (tension members),

- Web members (diagonal/vertical braces) 8.

This design prevents deformation under extreme conditions, such as heavy snow loads (up to 300 psf in Alaska) or wind uplift forces (common in hurricane-prone regions like Florida) 13.

2. Key Determinants of Load Capacity

Material Strength

- Steel Trusses: High-grade steel can support up to 30 tons of distributed load, ideal for industrial buildings. Hybrid systems combining steel connectors with timber are cost-effective for residential use 1314.

- Engineered Timber: Glulam beams offer a 20% higher strength-to-weight ratio than traditional lumber, handling dynamic loads like HVAC systems (10–15 psf) 13.

Span and Pitch

- A 40-foot-wide truss with a steep 6:12 pitch supports 40% more snow load than a flatter 4:12 design. However, steeper pitches increase material costs 8.

Building Codes

- U.S. standards like ASCE 7-22 mandate minimum loads:

- Snow Loads: Up to 150 psf in Colorado’s mountains.

- Wind Uplift: 120+ mph resistance in coastal zones 13.

3. Modern Innovations in Truss Design

- Computational Modeling: Tools like SAP2000 optimize member sizes, reducing material waste by 25% while maintaining load capacity 8.

- Prefabricated Systems: Modular steel-triangle units enable rapid installation—e.g., a Texas hotel achieved a 100-foot-span roof in 48 hours with 200 psf capacity 14.

- Smart Monitoring: IoT sensors in Chicago high-rises track stress and temperature, preventing overload risks 13.

4. Global Applications and Case Studies

Harbin Dongan Building Sheets Co., Ltd.

This Chinese manufacturer specializes in energy-efficient steel trusses for large-span structures. Their projects include:

- Intelligent Warehouses: Custom triangular trusses with 50-ton load capacity, integrated with solar panels and IoT stress sensors.

- Cold-Climate Adaptations: Double-layered steel trusses for Siberian logistics hubs, engineered to withstand -40°C temperatures and 200 psf snow loads.

International Examples

- Arizona Sports Arena (USA): A 200-foot clear-span steel truss supports solar panels (+5 psf) and HVAC systems, with cross-bracing to manage thermal expansion in desert heat 13.

- Alaska Research Facility (USA): Double-layered trusses with ¼-inch steel plates endure 300 psf snow loads, incorporating a 15% safety margin for ice buildup 14.

- Norwegian Arctic Museum: Glulam triangular trusses with hybrid steel joints resist 250 psf snow loads while maintaining aesthetic timber finishes 8.

5. Maintenance and Compliance

- Annual Inspections: Check for rust (steel) or termite damage (timber) 13.

- Post-Storm Reviews: Verify joint integrity after extreme weather events.

- Coatings: Elastomeric coatings extend steel truss lifespan by 20 years in coastal salt air 14.

Conclusion

Triangular roof trusses exemplify the fusion of geometry, material science, and modern engineering. From Harbin Dongan’s intelligent manufacturing to Arizona’s solar-integrated arenas, these systems redefine structural resilience. For architects and builders, prioritizing local codes, material innovation, and smart monitoring ensures trusses not only bear weight but also future-proof buildings against evolving climatic challenges.

Leave A Comment