Introduction

When selecting construction materials for commercial or industrial projects in the U.S., understanding the distinctions between PU/PIR sandwich panels and traditional foam core panels is critical. Both options feature durable outer layers designed for protection, but their core materials, performance characteristics, and applications vary significantly. This guide breaks down their differences, focusing on material composition, manufacturing processes, and real-world benefits to help builders and architects make informed decisions.

Core Material Composition

The most notable difference lies in the core material:

- PU/PIR Sandwich Panels: Utilize a high-performance polyurethane (PU) or polyisocyanurate (PIR) core. These materials are synthesized by combining polyether (white material) and isocyanate (black material) under high-pressure mixing. The result is a rigid foam with superior thermal resistance (thermal conductivity: 0.021 W/m·K) and fire safety ratings (B1/B2/B3).

- Foam Core Panels: Typically use polystyrene (EPS) or polyurethane foam with lower density and insulation efficiency. These cores lack the advanced chemical stability and fire-resistant properties of PU/PIR.

Manufacturing Process

PU/PIR Panels require specialized continuous production lines to ensure precision:

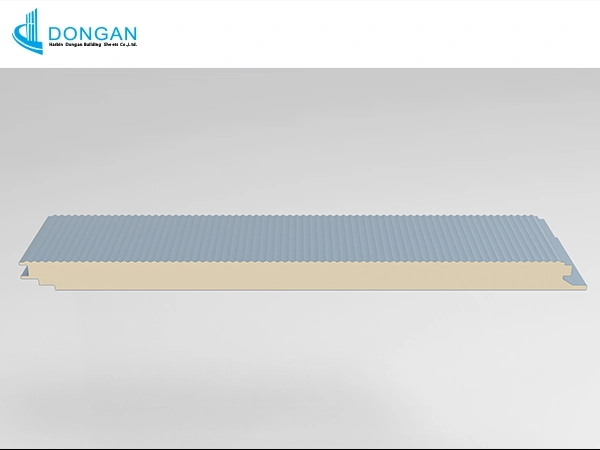

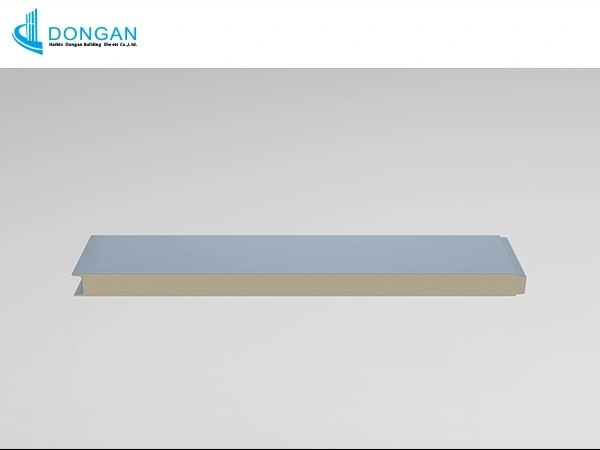

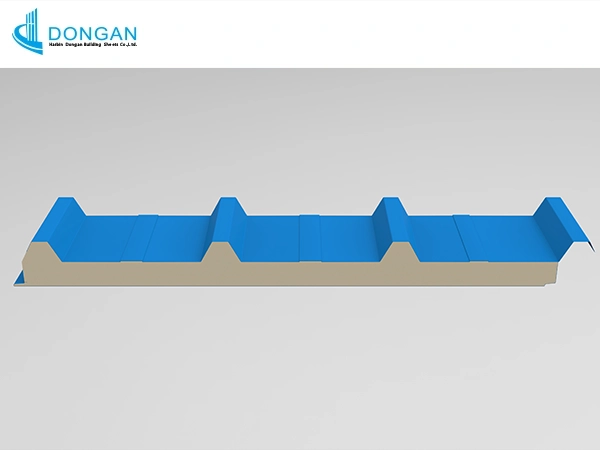

- Surface Preparation: Cold-forming galvanized or aluminum-zinc coated steel sheets into desired profiles.

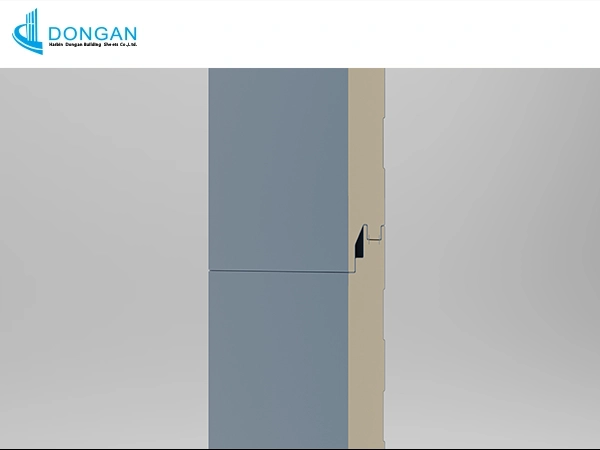

- Core Injection: High-pressure machines mix polyether and isocyanate at precise ratios, injecting the blend between the metal layers.

- Lamination & Curing: The composite undergoes controlled foaming and curing to achieve uniform density (40 kg/m³) and structural integrity.

Foam core panels, in contrast, often involve simpler processes like adhesive bonding pre-formed foam slabs between panels, which can lead to weaker seams and thermal bridging risks.

Performance Advantages of PU/PIR Panels

- Thermal Efficiency: With a 98% water repellency rate and near-zero thermal bridging, PU/PIR panels outperform foam cores in insulation, ideal for cold storage and energy-efficient buildings.

- Fire Safety: Rated B1/B2/B3, PU/PIR cores resist ignition and slow flame spread, meeting stringent U.S. building codes.

- Durability: Lightweight yet robust, these panels withstand extreme temperatures and moisture without warping.

- Aesthetic Flexibility: Available in 50mm–100mm thicknesses, with options for smooth, corrugated, or hidden-fastener finishes.

Applications in U.S. Construction

- Temporary & Permanent Structures: Offices, warehouses, and perimeter fencing benefit from quick installation and reusability.

- Cold Storage Facilities: Superior airtightness prevents condensation, maintaining consistent temperatures.

- Commercial Buildings: Pre-finished surfaces eliminate secondary needs, reducing project timelines.

Cost Efficiency & Sustainability

While PU/PIR panels may have a higher upfront cost than foam cores, their long-term savings are substantial:

- Reduced Energy Bills: Enhanced insulation lowers HVAC demands.

- Recyclability: Metal skins and stable cores allow material reuse across projects.

- Lower Labor Costs: Modular designs enable rapid assembly, cutting onsite.

Conclusion

For U.S. builders prioritizing energy efficiency, fire safety, and durability, PU/PIR sandwich panels offer a technologically advanced alternative to traditional foam cores. Their precision engineering, adaptability to diverse climates, and compliance with modern construction standards make them indispensable for sustainable, high-performance building solutions.

By integrating these panels into your next project, you not only future-proof structures but also align with growing demands for eco-conscious, cost-effective materials in the American market.

Leave A Comment