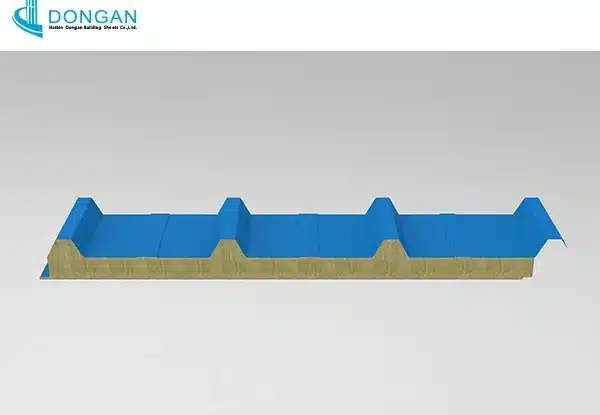

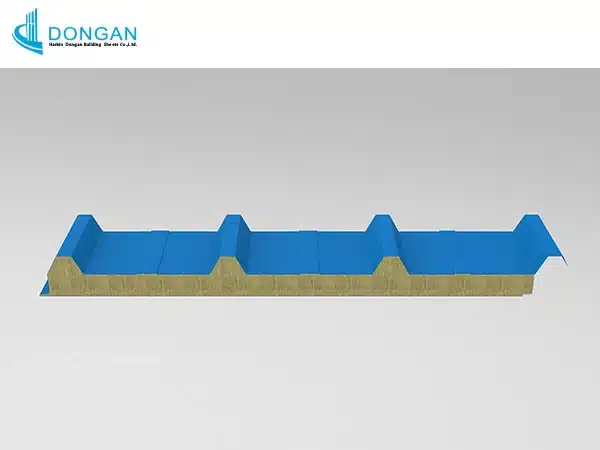

With more need than ever for energy-efficient, fireproof, and lightweight building material in today’s construction age, sandwich panel remains the best-selling item in the market. Consisting of an insulating core substance and two outer coverings (usually metal sheets), the sandwich panel offers class-leading thermal insulation, soundproofing, and quick installation benefits. Two of the most well-known are the pure rock wool sandwich panel and the EPS sandwich panel. They both possess qualities suitable for specific project requirements.

What is a Sandwich Panel

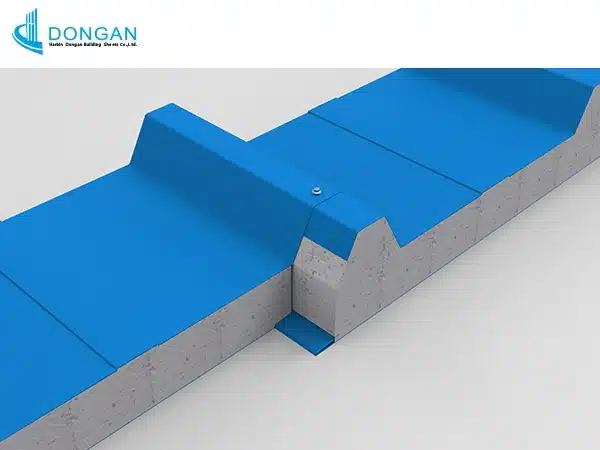

A sandwich panel is a composite that is made up of two outer metal skins and a core material inserted between them. It provides structural strength and insulation. The panels are extensively used in industrial buildings, warehouses, cold storage, and commercial and residential buildings.

Sandwich panels are widely used due to their easy installation, light weight, and excellent thermal insulation performance. Sandwich panels may be designed according to fire resistance, thermal conductivity, and sound insulation requirements, depending on the insulation core.

EPS Sandwich Panel: Economical and Light

An EPS sandwich panel is constructed using expanded polystyrene (EPS) foam as the core component. EPS is a low-density insulating material with thermal insulation capacity. EPS sandwich panels are particularly constructed for use in regions requiring a more affordable option without diluting the basic needs of insulation.

Key Benefits of EPS Sandwich Panels:

- Lightweight – The EPS core allows the panels to be light for transportation and hauling with less labor costs and construction time.

- Thermal Insulation – EPS is excellent at having thermal resistance that prevents interior temperatures from fluctuating.

- Cost-Efficient – EPS sandwich panels are one of the lowest-cost material solutions for mass construction.

- Moisture Resistance – EPS is low in water absorption and therefore it is the best choice for moderate climatic conditions.

Despite the advantages, EPS sandwich panels are completely lacking in fire resistance. EPS sandwich panels are inflammable and may not achieve rigorous fire protection standards, and therefore, alternatives like pure rock wool sandwich panels are generally adopted in high-risk areas.

Pure Rock Wool Sandwich Panel: Fire-Resistant Insulated Colossus

Pure rock wool sandwich panels are made up of rock wool (mineral wool) placed between. Rock wool is an inorganic, fire-resistant material that is recycled as a by-product when natural basalt rock is exposed to very high temperatures. The panels are thus provided with enhanced fire resistance, acoustic insulation, and load-carrying capacity.

Advantages of Pure Rock Wool Sandwich Panels

- Great Fire Rating – As fireproof as up to 2 hours or longer, pure rock wool sandwich panels of pure rock wool are ideal for fire-hazard areas or buildings where a very strict fire code is being implemented.

- Great Sound Insulation – Rock wool density makes the panels ideal for sound-sensitive uses such as recording studios, factories, or city offices.

- High Structural Strength – They are strong and can withstand high loads and be utilized in roofs, walls, and partitions.

- Sustainability – Rock wool is recyclable and environmentally friendly, and even encourages sustainable building techniques.

Though pure rock wool sandwich panels are costlier than EPS sandwich panels, the safety and durability are worth it in the long duration of time quite. Typically, pure rock wool sandwich panels will cost more, especially in commercial and industrial applications.

Choosing the Right Panel for Your Application

When selecting a sandwich panel, consider the specific requirements of your project. The following is a brief comparison:

| Feature | EPS Sandwich Panel | Pure Rock Wool Sandwich Panel |

| Weight | Lightweight | Heavier but more robust |

| Insulation | Good thermal insulation | Excellent fire and sound insulation |

| Fire Resistance | Low | High |

| Cost | Lower | higher |

| Applications | Cold rooms, temporary buildings | Factories, fire-rated buildings |

And if your building is in scenarios where fire protection and sound dampening are of the highest priority, such as power plants and chemical plants, then the pure rock wool sandwich panel is the answer. Alternatively, if weight and expense are of primary concern, then the EPS sandwich panel is the preferred option.

Conlusion

The use of sandwich panels has revolutionized the way we build today, allowing us to build faster, safer, and more efficiently. Whether you go for a pure rock wool sandwich panel for miraculous fire-resistant traits or an EPS sandwich panel for affordability and easy construction, both are highly advantageous depending on your individual project needs.

Knowing the material properties and use conditions for every variety of panel ensures your building is compliant with all performance and safety standards. As building codes continue to advance, the future of building construction will increasingly depend on high-performance products like sandwich panels.