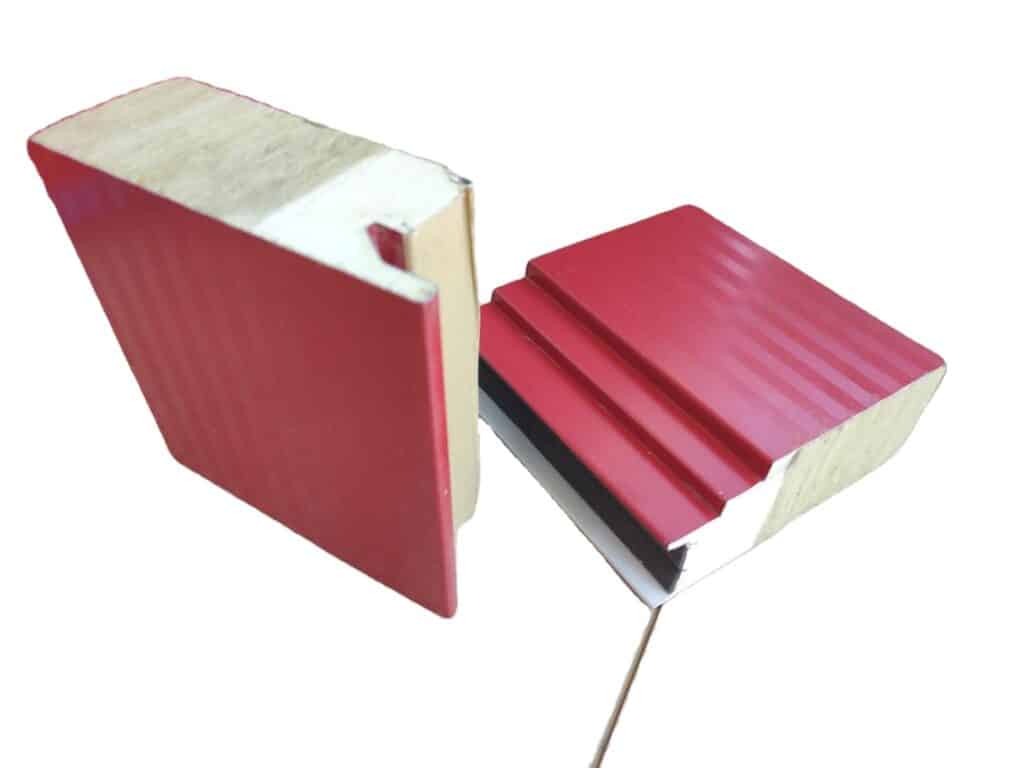

Polyurethane edge-sealed rock wool sandwich panels are a new generation of composite material sandwich panels. Rock wool remains the main filling inside this panel, and there are polyurethane material on both sides. This type of sandwich panel has achieved great success since its launch and has become a star product favored by both designers and construction parties.The reason for this is that polyurethane edge-sealed sandwich panels inherit the advantages of rock wool sandwich panels while addressing their shortcomings.

The advantage

- Outstanding thermal insulation performance.

Polyurethane foam material has a low thermal conductivity coefficient, and the sandwich panel can effectively block the thermal bridge effect, reducing the heat transfer coefficient. This characteristic allows buildings to maintain stable indoor temperatures in extreme cold or heat, saving air conditioning and heating energy consumption.

- Excellent waterproof performance.

The polyurethane material surrounding the rock wool forms a high airtight layer. It effectively prevents the lateral infiltration of rainwater, melted snow, and humidity. This effectively solves the problem of large gaps in rock wool panels, which are easily penetrated by rainwater. It keeps the rock wool material dry over the long term and extends the service life of the building. - Exceptional fire resistance.

The fire resistance of polyurethane edge-sealed sandwich panels meets Class A standards. Polyurethane foam material is non-combustible and can work in synergy with rock wool, which also has Class A fire resistance. In the event of a fire, the new panel will not produce dripping materials and will not release toxic smoke. This not only helps slow the spread of a fire but also buys time for personnel evacuation and firefighting rescue. - Stronger structural rigidity.

Polyurethane material allows rock wool and color steel plate to be fully combined. This enhances the stability and durability of the panel’s structure.

- Convenient and quick installation.

Dongan Building Sheets’ polyurethane edge-sealed rock wool panels prioritize ease of installation in their design. This can significantly shorten the construction cycle and reduce the risks of crossover operations.

Dongan`s polyurethane edge-sealed rock wool sandwich panels

In conclusion, this new type of panel deeply integrates the excellent sealing properties of polyurethane with the efficient thermal insulation properties of rock wool. It achieves simultaneous upgrades in thermal insulation, waterproofing, fire resistance, and structural integrity.

Harbin Dongan Building Sheets, as a leading sandwich panel manufacturer in China, continues to provide high-quality polyurethane edge-sealed rock wool sandwich panels to construction parties and designers around the world.

Leave A Comment