Refrigeration systems constitute the backbone of secure food storage, drug conservation, cold-chain supply chain, and industrial processes in modern industries. At their core developed in these systems developed state-of-the-art technology designed to drive optimum efficiency, reliability, and sustainability. One such hallmark solution that has garnered extensive media attention is the Bitzere screw two parallel (750) design, particularly when applied in conjunction with high-performance condensing units. By combining powerful engineering and innovative cooling methods, this technology is transforming the way industrial refrigeration equipment operates.

The Role of Condensing Units in Refrigeration Machines

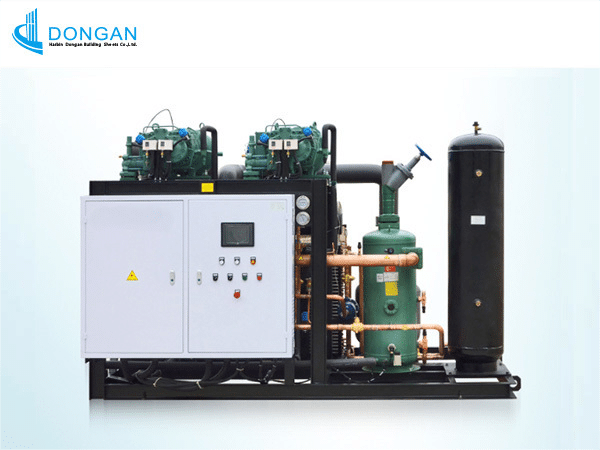

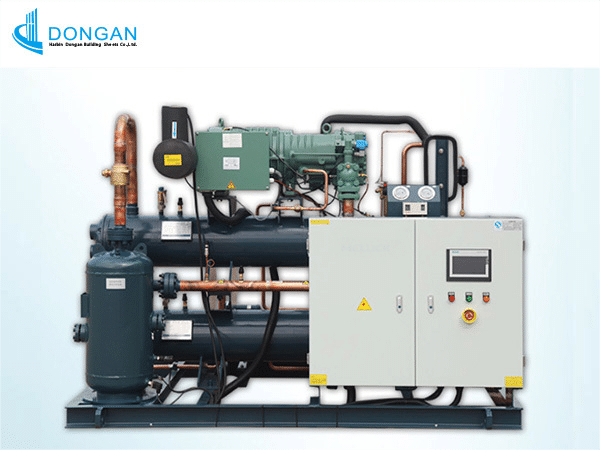

The condensing unit is the powerhouse of industrial refrigeration machines. The unit compresses the refrigerant vapor and releases heat, thereby facilitating efficient cooling cycles. In big machinery refrigeration machines, such as cold storage houses, food processing units, and distribution warehouses, the condensing unit directly affects power consumption, cooling stability, and long-term operating costs.

The traditional condensing units have given loyal service through the decades, but today’s industries require more efficiency, less carbon footprint, and a greater ability to handle workload. That is where the Bitzere screw two parallel (750) configuration is a game changer.

What is Bitzere Screw Two Parallel (750)?

Bitzere screw two parallel (750) is a two-screw compressor configuration designed for bulk volume use. Unlike traditional single-screw configurations, the parallel configuration accommodates two compressors working together or individually, depending on cooling capacity. This enables companies to maximize energy usage, reduce mechanical stress, and increase the life of primary refrigeration equipment.

The “750” designation basically stands for the capacity class, and therefore particularly convenient for high-demand applications where efficiency and consistency are not an extravagance. Paired with a modern condensing unit, this system offers better performance for industrial applications of a big scale.

Advantages of Bitzere Screw Two Parallel (750) in Condensing Units

1. Energy Efficiency

The major advantage is the modulating capability of cooling. Low loads have one compressor operating, saving energy. At high load ratings, the two compressors operate in parallel without interfering with the cooling operation. Dynamic operation saves tremendous amounts of energy during the year.

2. Increased Reliability

In mission-critical applications like drug storage or frozen food distribution, system downtime can lead to ruinous losses. Bitzere screw two parallel (750) redundancy offers a standby so that if one of the compressors needs maintenance, the other can continue to operate. It enhances the reliability of the condensing unit and minimizes expensive downtime.

Having two screw compressors share the load also reduces mechanical wear and tear. This means that the refrigeration equipment lasts longer, with savings in replacement costs and a better return on investment.

3. Increased Cooling Capacity

With its capacity to support high cooling loads, Bitzere screw two parallel (750) is most suitable in all such industries where there will be a need for continuous and intense cooling. It supplies constant temperatures, protecting sensitive products as well as gaining regulators’ consent.

4. Environmental Advantages

Efficient performance reduces the amount of greenhouse gas emissions released. The majority of the new condensing units that come pre-integrated with this system have been made compatible with eco-friendly refrigerants in an effort to assist in guaranteeing sustainability.

Applications in Modern Refrigeration Equipment

The Bitzere screw two parallel (750) used in condensing units is traditionally used in:

- Cold storage warehouses where uniform and stable low temperatures are necessary.

- Factories producing foods and beverages where safety and freshness depend on efficient cooling.

- Pharmaceutical and biotechnology complexes where temperature control for sensitive products is necessary.

- Distribution centers and logistics where high capacities of goods pass through temperature-controlled environments.

With such state-of-the-art technology, businesses keep their refrigeration equipment running as efficiently as they can and down less often.

Future Prospect

Environmental responsibility and energy conservation will take the world’s industries into the future, and new-generation condensing units will render technologies like the Bitzere screw two parallel (750) standard passé. Continuous innovation in compressor engineering, refrigerant compatibility, and electronic monitoring will further improve performance, allowing companies to exercise more control over refrigeration systems.

Conclusion

The integration of the Bitzere screw two parallel (750) into modern condensing units is a gargantuan move towards industrial refrigeration technology. With its increased efficiency, reliability, and eco-friendliness, the technology not only responds to the current needs of industries but also to future ambitions in the areas of energy and environmental preservation. To businesses that seek to maximize operational efficiency without compromising the integrity of sensitive temperature-based products, investment in this innovation solution is a business decision.