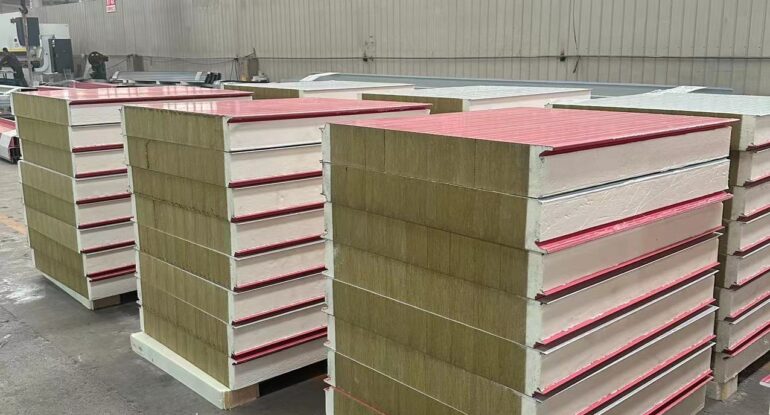

Rock wool sandwich panel is a widely used building board. This kind of sheet has a fireproof function, but also keeps the indoor temperature stable and reduces the electricity consumed by the air conditioner. On the walls and roofs of many buildings, we can see rock wool sandwich panels. Therefore, the quality of rock wool sandwich panels directly affects the performance and life of the building. It becomes very important to choose high-quality rock wool sandwich panels.

Performance indicators of rock wool sandwich panels

Rock wool is the core material of sandwich panels. Therefore, the quality of rock wool determines the performance of the sandwich panel.

The bulk weight index is an important indicator in measuring the quality of rock wool core material. The bulk-weight index reflects the tightness of rock wool fibers. The higher the bulk-weight index, the tighter the rock wool fiber, and the stronger the compressive and tensile properties.

But the bulk-weight index is not as high as possible. Different usage scenarios have different optimal indices. For example, for sandwich panels installed on the roof, the optimal bulk weight index is 100-120 kg per cubic meter. The rock wool board of this index can not only ensure the structural strength, but also control the weight and reduce the load-bearing of other structures.

The thermal conductivity is also very important. The thermal conductivity is an important indicator to measure the thermal insulation ability of rock wool materials. The lower the thermal conductivity, the better the thermal insulation effect. Especially in high-latitude regions such as Russia and Canada, high-quality rock wool panels can effectively ensure indoor temperature and reduce the energy consumed by building heating.

The hydrophobicity rate is also an important indicator to measure the quality of rock wool materials. Because the rock wool core material is composed of countless rock wool fibers, there is a certain gap between the fibers. Moisture can penetrate into the interior of the sandwich panel through these gaps, corroding the plate. Rock wool with high hydrophobicity can effectively reduce the penetration of moisture and avoid the performance degradation of the sandwich panel. Generally speaking, the hydrophobicity of rock wool core material should not be lower than 98%.

As an important accessory to protect the core material and support structure, the quality of the metal panel is also very important. Common metal panels are color-coated steel plates and galvanized steel plates. The thickness of the metal panel determines the physical properties and structural strength of the sandwich panel. But like the bulk-weight index, the thickness of the metal panel is not as thick as possible. The thickness of the metal panels of different types of sandwich panels is different. For example, the panel thickness of the sandwich wall panel is 0.4-0.6 mm. The thickness of the metal panel of the sandwich roof panel is 0.5-0.8 mm. Such a design can not only meet the structural strength, but also reduce costs.

Leave A Comment