The installation of rock wool sandwich panels is an important step in building decoration. At the same time, it reflects the product design capabilities of the manufacturers.

As a mature building material, rock wool sandwich panels have a wide range of applications in the construction field. Rock wool sandwich panels are commonly used for constructing walls and roofs. The excellent thermal insulation performance and outstanding fire resistance characteristics of rock wool sandwich panels have made them popular in the market. Moreover, their installation has a critically significant impact on the quality and performance of the entire building structure.

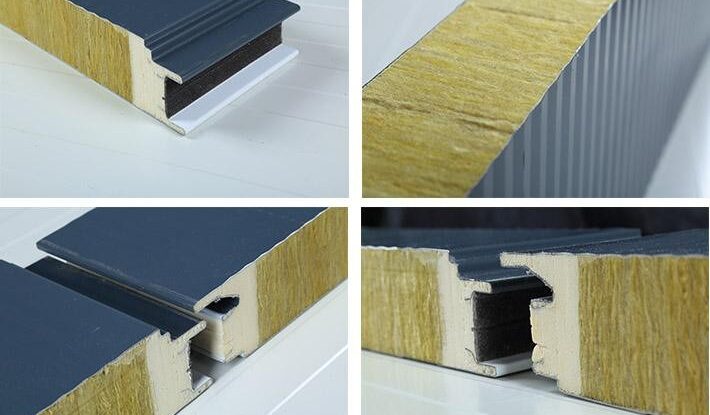

Currently, there are two main installation methods for rock wool sandwich panels,the tongue-and-groove joint and bell-and-spigor joint.

The Bell-and-spigor joint refers to inserting one side of the sandwich panel into the slot of another panel. This connection method is similar to two spliced water pipes, where the inserted end completely covers the installation interface. This provides stable connectivity for the panels. Additionally, this connection method endows the panels with excellent structural strength. Such spliced panels can easily withstand external impacts such as wind force.

However, this installation method can cause different thicknesses on both sides of the panels. As a result, the panels cannot form a smooth surface after splicing.

Mainstream rock wool sandwich panel installation method

The tongue-and-groove joint refers to directly inserting the edge of the sandwich panel into the slot of another sandwich panel, similar to how blocks are connected together. This installation method not only provides a certain degree of structural strength but also simplifies the process. Furthermore, the flat surface makes the appearance of the installed panels more aesthetically pleasing. Therefore, the tongue-and-groove joint has become the predominant installation method for rock wool sandwich panels nowadays.

Although the tongue-and-groove joint has many advantages, it places higher demands on the design and production levels of manufacturers. The splicing of the panels requires a certain structural strength to prevent the panels from cracking and falling apart due to external impacts. At the same time, it is essential to minimize the difficulty of splicing and reduce construction time. This requires manufacturers to carry out targeted design for the interfaces based on the physical properties of the panels they produce.

As a leading sandwich panel manufacturer in China, Harbin Dong’an Building Sheets Company has extensive production design experience. The sandwich panels produced by Dongan are typically equipped with tongue-and-groove connections on both sides. This allows for higher precision and greater stability in the installation of the panels. Additionally, the intricate design at the connection points improves the air tightness of the panels, effectively avoiding the occurrence of thermal bridge conduction. While ensuring excellent waterproof performance, the design of the interfaces also facilitates the quick loading and unloading of the panels, providing convenience for later maintenance. Relying on rich design experience and strong production capacity, Dong’an Company continues to provide excellent rock wool sandwich panel materials to customers globally.

Leave A Comment