Refrigeration equipment finds application across numerous industries, varying from food storage to air conditioning units and industrial cooling plants. At the center of all these is the condenser, the most crucial piece of equipment for heat dissipation and refrigerant condensation. Among all the different types of condensers, the FNV condenser is the one that has undergone a revolution with enhanced efficiency and sustainability. Their impact on the refrigeration machines, FNV condenser features, applications in the modern refrigerating systems, as well as the way they assist the industry is presented in this article.

The Application of Condensers in Refrigeration Systems

The role played by the condenser in a refrigeration cycle is very crucial as regards heat exchange. After the refrigerant has gained heat via the evaporator, it is passed through the compressor, where its pressure and temperature are boosted. The high-pressure hot gas is then sent through the condenser, where it is reduced to the ambient environment as heat and condenses into a liquid.

There are several other kinds of condensers used in refrigeration systems:

- Air-cooled condensers – Employ fans for heat transfer to air.

- Water-cooled condensers – Employ water flow for cooling.

- Evaporative condensers – Employ combined air and water cooling for more efficiency.

The efficiency of the refrigeration system largely relies upon the performance of the condenser. A better condenser allows maximum heat transfer, reducing energy cost and system efficiency.

What is an FNV Condenser?

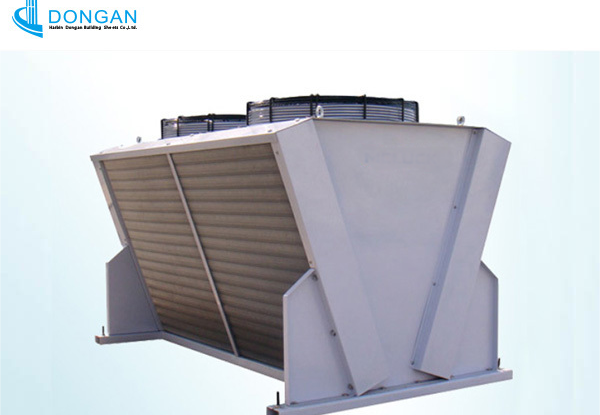

The FNV condenser (Flat Natural Ventilation condenser) is a modern, air-cooled condenser with enhanced heat transfer and energy efficiency. The FNV condenser, unlike other condensers, is a flat panel condenser with aerodynamically configured airflow channels, permitting natural or forced ventilation at very low energy input.

Key Features of FNV Condensers

- Space-Saving Compact Design – FNV design aims to occupy the smallest overall footprint at an absolute minimum, ideally for refrigeration purposes where space is an issue.

- Enhanced Heat Transfer Efficiency – The new fin-and-tube design of FNV offers optimal surface area for optimal heat transfer.

- Quieter Operation – Smooth airflow makes FNV condensers run quieter than their standard counterparts.

- Energy-Efficient Operation – Reduced fan power requirement translates to lower electricity bills.

- Long-lasting and corrosion-resistant – FNV condensers are constructed with heavy-duty materials like plated copper or aluminum and are also resistant to corrosion, providing maximum life for refrigeration equipment.

Applications of FNV Condensers in Modern Refrigeration Equipment

FNV condenser is increasingly applied in the new refrigeration equipment due to its improved performance. Some of its most significant applications are:

1. Commercial Refrigeration

Commercial stores, cold storage plants, and food processing plants require refrigeration equipment. FNV condenser provides uniform temperatures with energy cost savings.

2. HVAC Systems

For air conditioners, the FNV condenser provides improved cooling performance, therefore, it can be utilized for domestic and commercial HVAC systems.

3. Industrial Refrigeration Equipment

Industrial plants and data centers use high-capacity refrigeration equipment. Heavy-duty construction facilitates the operation of the FNV condenser continuously even during heavy loads.

4. Eco-Friendly Refrigeration Solutions

According to the policy of sustainability being of prime importance, FNV condensers allow the utilization of low-GWP (Global Warming Potential) refrigerants so that easy compliance with environmental regulations is facilitated.

Advantages of FNV Condensers in Refrigeration Equipment

The benefits of FNV condensers in refrigeration devices consist of improved energy efficiency achieved through an increase in heat transfer through reduction of compressor load, thus conserving energy.

- Less Maintenance Cost – Their rigid nature creates less wear and tear, therefore less maintenance time and expense.

- Increased System Life – Heat dissipation prevents system overheating and therefore enhances system life.

- Environmental Benefits – Reduced energy consumption means reduced carbon footprint, an environmentally friendly boost to the initiative.

- Installation Flexibility – Because it is so compact in size, it can be readily incorporated into existing refrigeration systems.

Conclusion

The condenser is one of the most important parts of refrigeration equipment with direct impacts on system reliability and efficiency. FNV condenser is a new type of condenser that provides more heat dissipation, energy efficiency, and reliability. With increasing innovations in refrigeration equipment towards increased efficiency and environmental friendliness, FNV condensers will be part of refrigeration equipment in the future. With composite FNV condensers, businesses and consumers can enjoy higher performance, lower operational cost, and lower environmental footprint, and thus offer a superior future choice in refrigerator technology.