Description

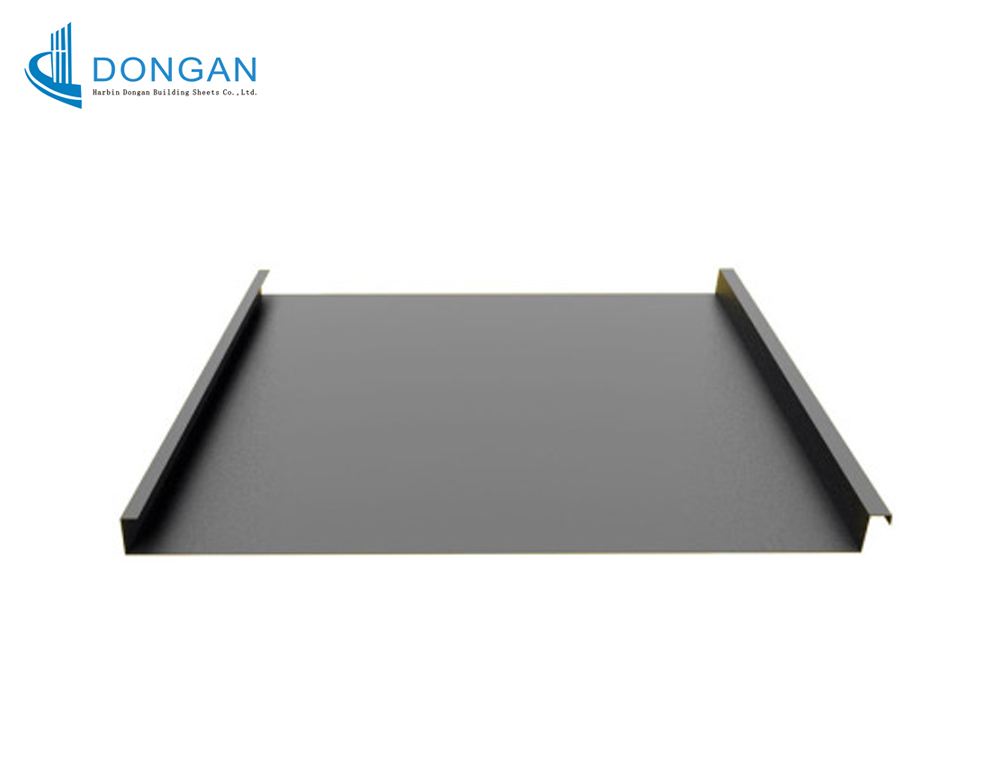

Al-Mg-Mn Panels from DONG`AN

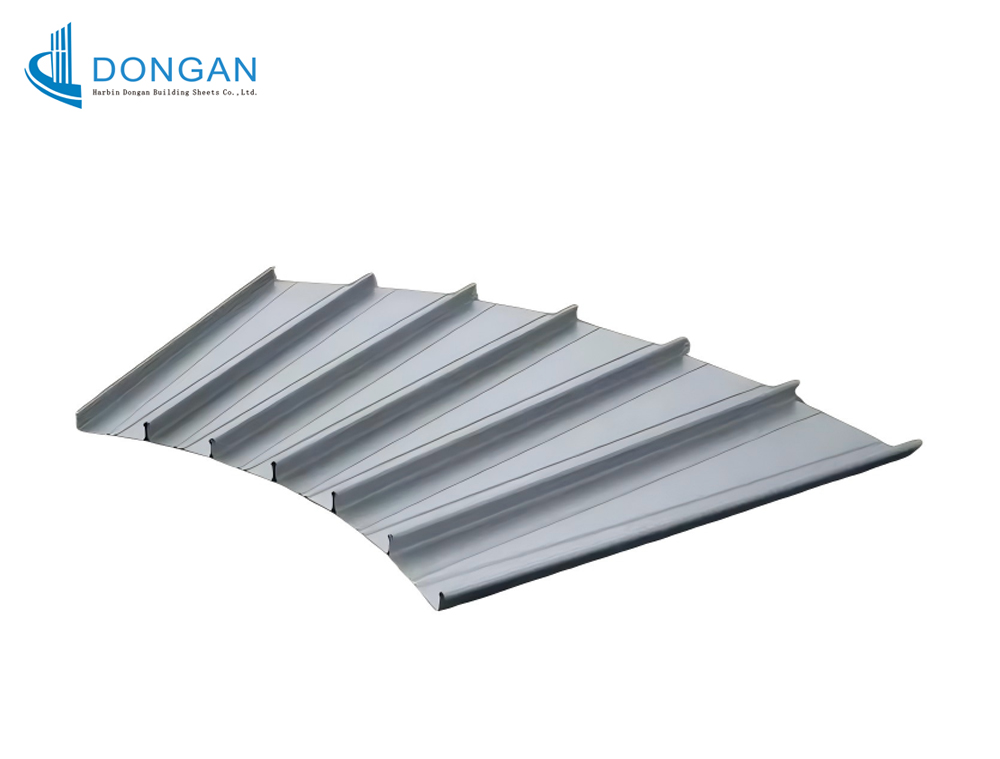

Al-Mg-Mn panels are a new generation of building materials.

Product classification

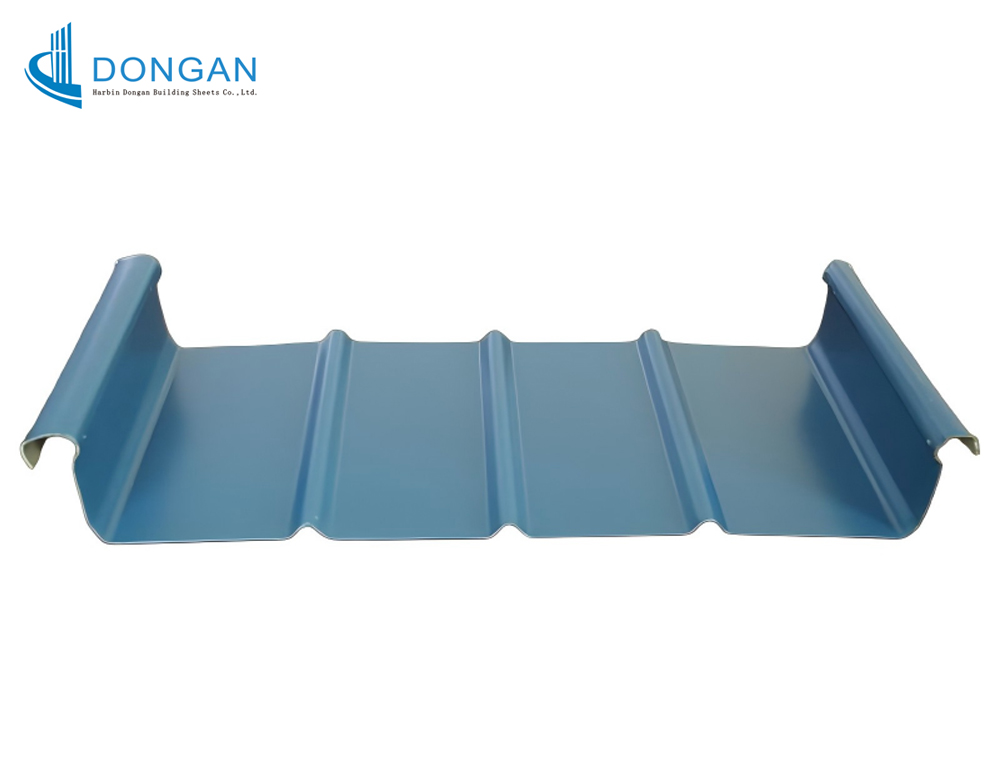

According to the different needs of use, people will choose aluminum alloy plates of different materials. At present, the common Al-Mg-Mn panels on the market mostly use AA3003 or 3004 Al-Mg-Mn alloy. The structural strength of the aluminum alloy plates of these two grades is moderate, which can meet the design needs of most buildings.

In addition, the material has a certain ability to resist corrosion, and the processing difficulty is low. The service life of the architectural design for the installation of Al-Mg-Mn wall panels and roof panels can reach more than 50 years.

If the building is located by the sea, you can also choose AA5052 aluminum alloy with stronger corrosion resistance, or even AA6061 aviation-grade alloy material. Although these two materials have better corrosion resistance, their hardness is high. Buildings with this kind of panel are also more difficult to construct.

Compared with common color steel plates, this product has many advantages. This is also an important reason why Al-Mg-Mn plates are becoming more and more sought after by the market.

The advantages of Al-Mg-Mn panels

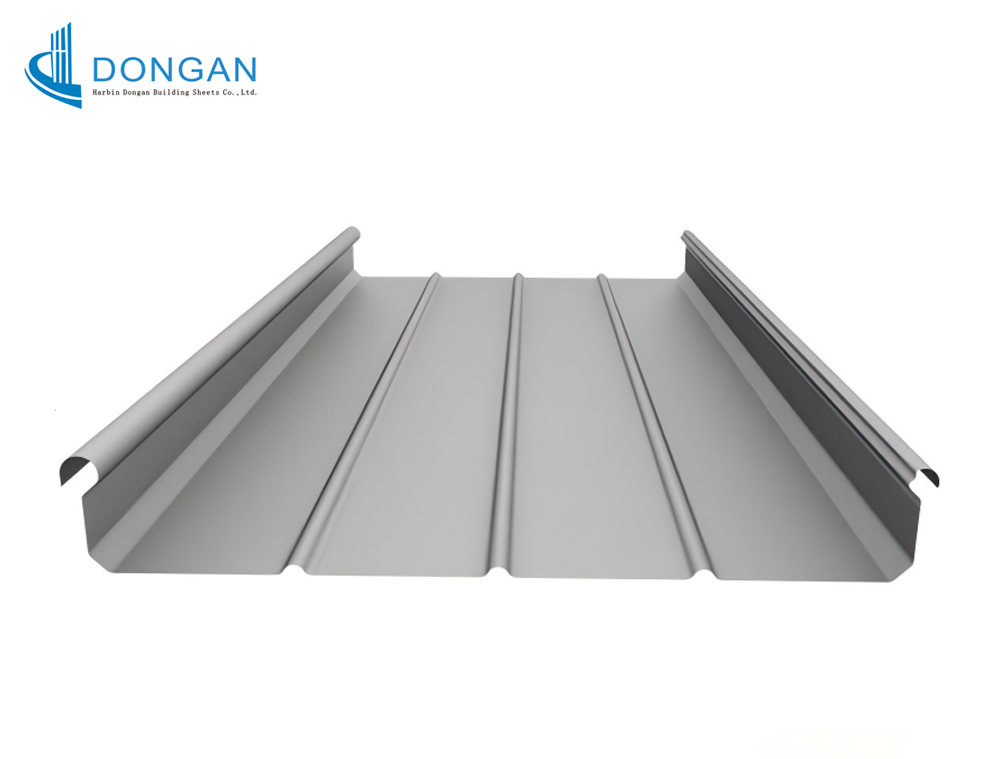

Lighter weight

The core material of Al-Mg-Mn plate is aluminum alloy. The density of aluminum is only about one-third that of stainless steel. Therefore, the weight of Al-Mg-Mn plates is lighter, providing more space and possibilities for architectural design.

Better durability

Because of the characteristics of the material, aluminum alloy will form an alumina film on the surface. This film will not spread rapidly, but will protect the internal material from erosion. In contrast, color steel plates will inevitably rust and corrode when they receive humid air or rain and snow. Therefore, the Al-Mg-Mn plate has a longer service life, and the maintenance cost of the building where the plate is installed is lower in the later stage.

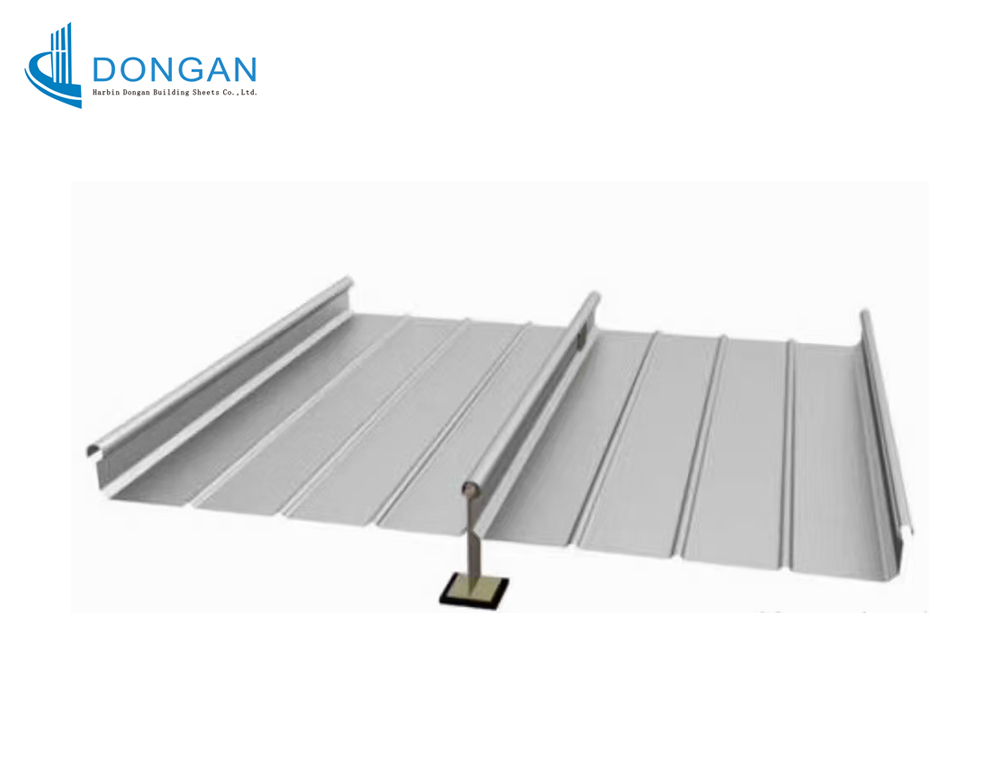

Higher security

Buildings with color steel roof panels need to install additional lightning rods .Only in this way can the roof of the building avoid being penetrated by lightning. The Al-Mg-Mn plate can be directly used as a lightning arrester, effectively reducing the threat of lightning to the building.

In addition, the melting point of Al-Mg-Mn plate is lower. When a fire occurs, the roof can be burned through. This allows firefighters to put out the fire from the roof, which is conducive to putting out the fire. The melting point of color steel plate is higher. When encountering a fire, the flame will spread laterally because of the flame retardant on the roof, which will make it difficult for personnel to escape and fight the fire.

Although Al-Mg-Mn plates have many advantages, color steel plates still have advantages in structural strength. However, thanks to the help of magnesium and manganese in the material, the strength of aluminum alloy materials can also meet the needs of most buildings. Therefore, Al-Mg-Mn plates still have a strong price performance.