With the demands of efficient and cost-efficient building systems in today’s building design, the demand for factory-built steel structures has grown. Among the most sophisticated solutions is the T-shaped truss roof, an innovative yet minimal-complexity design that meets strength, load, and material usage targets to the highest level. As a component of an integrated system of steel structures, the T-shaped truss offers unparalleled advantages in industrial, commercial, and residential buildings.

What is a T-Shaped Roof Truss?

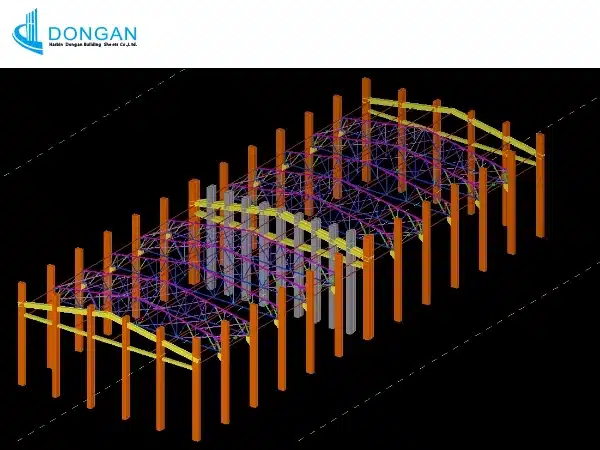

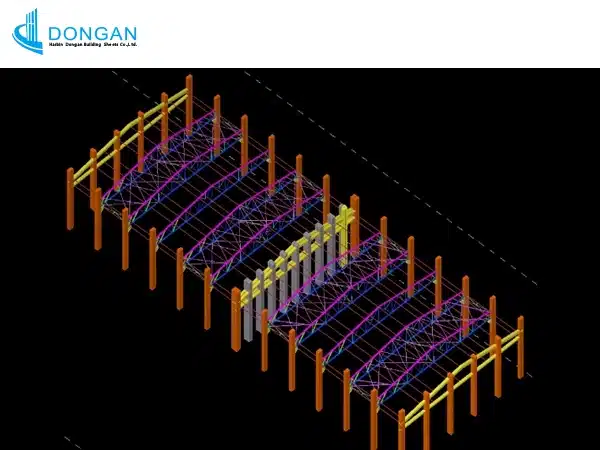

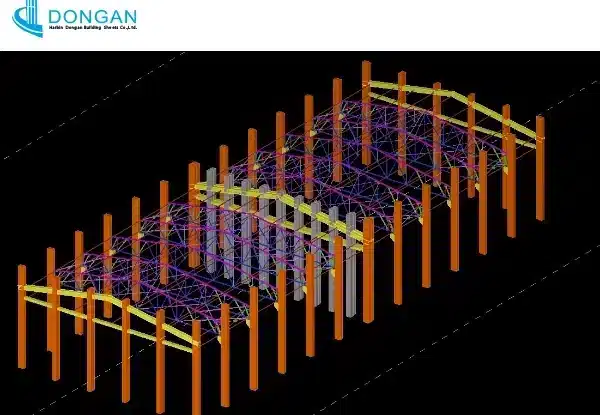

A T-shaped roof truss is a support structure consisting of triangular members with a T-shape when viewed from below or in cross-section. The truss distributes roof loads over long spans using fewer materials than traditional roof construction. The horizontal top of the “T” supports the roof surface, and the vertical stem contributes vertical load capacity and stability.

This sort of truss is particularly versatile for those buildings containing interior partitions or corridors like warehouses, factories, or expansive business complexes. It provides a structural support on which all the rest can emanate, and thus is perfectly suited to modular and growing building structures.

The role of T-Shaped Roof Trusses in Steel Construction

The use of T-shaped roof trusses in a steel structure system highly enhances the performance of an entire building. Steel is ductile and tensile, hence optimal to be used in conjunction with the geometric benefit of trusses. This amalgamation provides equitable distribution of loads within a building, reducing stress on a specific component.

In a pre-fabricated steel structure, T-shaped roof trusses facilitate precise engineering and prefabrication. All could be designed remotely using advanced CAD/CAM methods, prefabricated to the most precise specifications, and later installed in-place at last with minimal adjustment required. This not only minimizes construction time, but safety and quality control are enhanced as well.

Advantages of T-Shaped Roof Trusses

1. Minimum Load Distribution

T-shaped roof trusses maximally facilitate load distribution in both the horizontal and vertical directions. It is particularly applicable in the case of wide-spanned structures where uniformity of stress is essential to provide stability to the structure.

2. Material Optimization

Unlike usual beams or solid roofs, truss formation minimizes the usage of steel with a significant cost advantage without any loss of strength.

3. Architectural Flexibility

T-shaped roof trusses are more adaptable to building architecture. They can be designed to suit any roof slope and building design and can be used for an enormous variety of applications.

4. Simplified Design

Because the trusses are often pre-engineered inside a pre-fabricated steel structure frame, they are simpler to install in the field with fewer laborers. This reduces construction schedules and disruption in the surrounding environment.

5. Sustainability

Steel is also an extremely recyclable building material. Almost any T-shaped roof truss can be used in a steel structure to support sustainable building methods and green building practice, and legislation.

Applications of T-Shaped Roof Trusses

T-shaped roof trusses find applications in:

- Industrial structures: Factories and storehouses, for which open floor space and maximum bearing capacity are requirements.

- Commercial complexes: Shopping malls and exhibition halls that make use of wide roof spans and obstruction-free interior space.

- Agricultural buildings: Barns and processing houses, for which ventilation and obstruction-free space a key requirements.

In all of these environments, the reason that a steel frame is manufactured is to ensure the system is able to withstand dynamic loads, resist corrosion, and remain structurally sound for decades of service.

Engineering Considerations

Although the T-shaped roof truss is full of advantages, it needs to be well-engineered. Span length, roof pitch, wind load, snow load, and connection design are all factors that need to be well-calculated. Even the choice of steel grade and member size is a key factor in the efficiency and cost-effectiveness of the truss.

Coordination with experienced engineers and steel fabricators should be done to ensure the finished steel structure meets all functional and safety specifications. Computer software like finite element analysis (FEA) can be used to simulate stress areas and optimize geometry before fabrication.

Conclusion

The T-shaped roof truss is a robust solution to modern buildings, particularly as part of a constructed steel framework. Its ability to resist loads over extensive roof spans, reduce wastage material, and accelerate construction schedules makes it extremely popular with architects and engineers.

With the growing need for sustainable, scalable, and durable steel building structures, the T-shaped roof truss is a cornerstone technology. When designing an industrial plant facility, commercial warehouse complex, or large ag facility, incorporating T-shaped roof trusses in your building structure will be more than worth it in performance as well as long-term value.

Leave A Comment