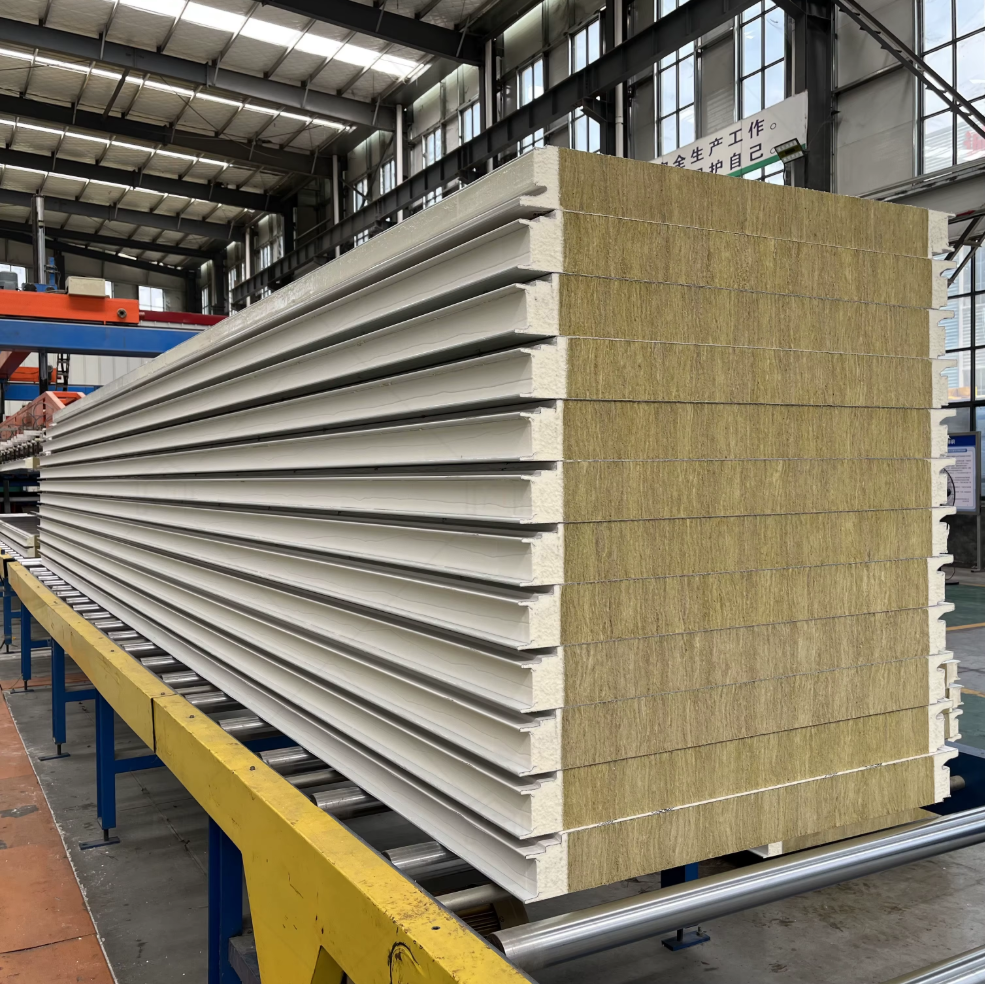

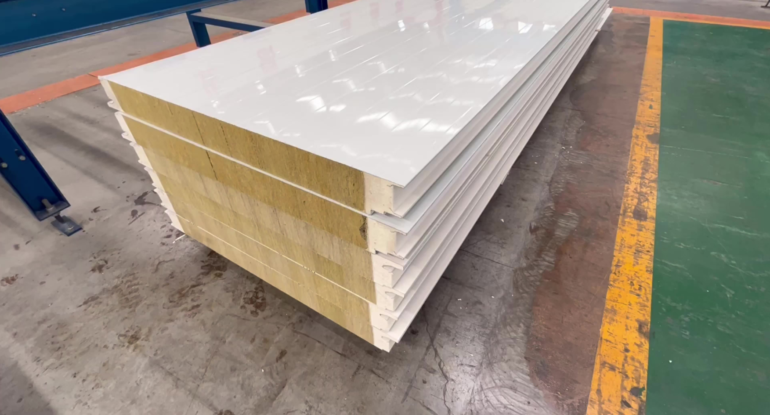

Common rock wool sandwich panel features two metal layers with a rock wool core in the middle. This structural design gives this material good physical properties and stable chemical properties. Rock wool sandwich panel is not only widely used in ordinary buildings, but also very popular in the construction of cold storage.

Good thermal insulation performance of rock wool cold storage board

Rock wool sandwich panels can become a common building material for cold storage projects, thanks to their good thermal insulation properties.

The core material of rock wool sandwich panel is natural rock fiber. Rock wool fiber has a high melting point, stable properties and strong durability. There are a large number of tiny voids between the fibers of the rock wool core material. On the one hand, this structure can hinder air convection and reduce the efficiency of heat conduction.

On the other hand, the presence of a large amount of air in the fiber voids can strengthen the thermal insulation capacity of the sheet. According to calculations, the thermal conductivity of rock wool sandwich panels is usually between 0.030-0.050W/(m·K). This kind of composite plate can effectively block the influence of external heat on the internal temperature.

Therefore, rock wool sandwich panels, like polyurethane sandwich panels, are more suitable building materials for cold storage. The practical results of many cold storage projects show that the cold storage built by rock wool sandwich panels can effectively ensure the stability of the temperature of stored items. At the same time, it can also improve the work efficiency of the refrigeration system and reduce the energy consumption of cold storage.

Excellent fire resistance of rock wool cold storage board

Compared with the mainstream polyurethane cold storage board, the core advantage of rock wool cold storage board lies in its excellent fire resistance. The materials of rock wool sandwich panels are metal alloys and rock fibers, both of which are fire-retardant and flame-retardant. Under high temperature roasting, rock wool will neither burn nor release toxic gases.

The fire rating of rock wool sandwich panels can reach grade A, which is better than Grade B1 PIR sandwich panels and grade B2 PU sandwich panels. The excellent fire resistance determines that rock wool sandwich panels are very suitable for markets such as the United States and Europe that require high fire resistance of buildings.

Good structural strength of rock wool cold storage board

In cold storage projects, engineers often place cold fans on top of the warehouse body for the best cooling effect. At the same time, in order to increase the loading capacity of cold storage, sometimes it is necessary to install racks and other devices on the warehouse body. This requires that the cold storage board needs to have a certain structural strength and can carry a certain weight.In addition, the environment with low temperature and high humidity in the cold storage also requires higher durability of building materials. Rock wool sandwich panels can meet these two needs.

The rock wool sandwich panel is made of a combination of metal panel and rock wool core material through a special process. The sheet itself has both the physical properties of metal panels and rock wool fibers, and has strong structural strength. Additionally, its physical properties remain strong over time. Excellent durability keeps the cold storage in good condition and lowers maintenance costs.

Easy to install and can be reused

Rock wool sandwich panels are lighter in weight, easy to transport and handle, and have a low loss rate. Moreover, during the construction process, people used splicing to install the sandwich panels together. The standardized production of rock wool sandwich panels ensures dimensional accuracy and makes the installation process more accurate and efficient. Manufacturers can flexibly design and customize these sheets to meet specific cold storage requirements.

Workers can reuse the sandwich panels even after dismantling them, which further increases the project’s economic benefits.

Disadvantages of rock wool cold storage board

Although rock wool cold storage boards have excellent overall performance, they also have disadvantages. The core material of rock wool sandwich panel is rock wool formed by mechanical pressing of rock fibers. However, the binding between the fibers is not close, and after a period of time, the fibers at the edges will break and fall off. This flaw compromises the board’s integrity, allowing water vapor to enter and reduce its insulation capacity.

In order to solve this problem, there are currently two solutions. One is to use a closed metal plate frame. People install metal plates on both sides of the rock wool sandwich panel to fix the two sides of the rock wool block that are easy to fall off and detritus. The other is to pour polyurethane foam material on both sides of the rock wool block. Manufacturers fix the rock wool block by expanding polyurethane material at high temperatures.

Leave A Comment