In the modern construction era, efficiency, durability, and flexibility of design have been more important than ever before. While engineers and architects have created innovative solutions for complex building structures and wide-span roofs, there has been a single structural member that has been a blessing time and again: the triangular roof truss. With the strength of a pre-fabricated steel building, the cornerstones of the structure are millions of industrial, commercial, and infrastructural projects worldwide.

In this blog, we’ll explore the importance of steel structures, the unique benefits of triangular roof trusses, and how they come together in modern fabricated steel structures to create robust, cost-effective, and sustainable buildings.

What is a Triangular Roof Truss?

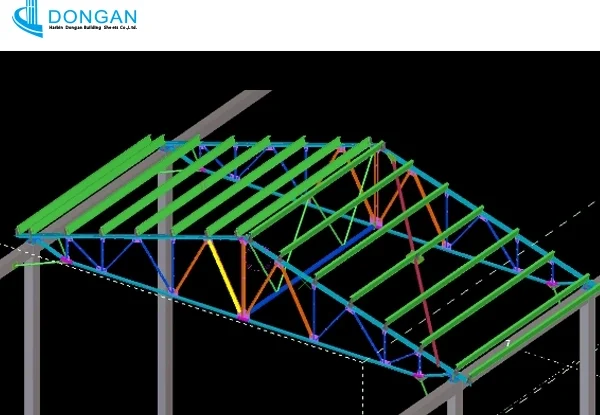

A triangular roof truss structure is an arrangement of members. The triangle is the most secure geometric shape in engineering, and in roofing, it provides weight distribution that is effective and can withstand external forces like wind and snow.

In contrast to the traditional rafters that depend a lot on vertical support posts, triangular roof trusses extend over much greater lengths without the use of such support posts. They are thus very well suited to big buildings such as warehouses, plane hangars, stadiums, factories, and even houses’ attics.

How Triangular Roof Trusses Support Steel Buildings

In a pre-fabricated steel building, the triangular roof truss system is a load-spreader. The triangle spreads roof loads evenly throughout the building and to the foundation, which removes points of stress.

Major Benefits:

- Material Efficiency

Triangular trusses reduce steel usage without diminishing strength. This saves costs and results in a lighter building overall.

- Clear Spans

Trusses offer broad open spans with no interior columns and are particularly suited for use in factories, gymnasiums, and warehouses.

- Ease of Integration

Ducts, piping, and lighting can be integrated within the open web of a triangular roof truss to achieve maximum overall design efficiency.

- Versatility

The trusses can be designed to different sizes, depths, and slope angles according to requirements to meet specific architectural and engineering requirements.

Fabricated Steel Structure: Efficiency and Accuracy

A fabricated steel structure is not just steel beams—imagine a whole building system that is efficient. Every piece, from columns to trusses, girders, and braces, is prefabricated off-site and transported to the job site for immediate installation.

And this is why fabrication is a game-changer for construction:

- Accuracy: CNC machines cut and drill parts with millimeter precision.

- Speed: With off-site prefabrication, labor cost savings, reduced construction time schedules, and increased safety are achieved.

- Flexibility: It is easy to make design changes during the engineering stage without expensive on-site adjustments.

- Sustainability: Steel is recyclable to 100%, and the minimized waste during fabrication meets sustainable building requirements such as LEED.

Where triangular roof trusses are included in a prefabricated steel building, they are favored by this step in the way that they are transported to the site in pre-fabricated parts, conserving building time and adding reliability.

Applications of Triangular Roof Trusses for Steel Structures

1. Warehouse Buildings

There is no need for interior supports for long spans to accommodate forklift traffic and the storage of goods. Triangular roof trusses offer the needed strength and openness.

2. Agricultural Structures

Farmers utilize low-maintenance, durable steel structures with efficient roof truss designs to shield equipment and crops from barns to storage structures.

3. Aircraft Hangars

The massive clear spans required by aircraft are enabled through manufactured steel frames specifically designed with assisted triangular roof trusses.

4. Arenas and Stadiums

Sporting facility rosters tend to use gigantic triangular roof trusses to enclose seating accommodations with an architectural style.

5. Commercial Complexes

Shopping centers and commercial centers benefit from the openness and long-term stability that a steel truss system provides.

Design Considerations for Engineers

The following must be considered by engineers while designing a steel building’s triangular roof truss:

- Span and load conditions

- Slope of the roof and climatic loads (snow, wind, seismic)

- Connection types (bolted or welded)

- Protection against corrosion (galvanization or painting)

- Future expansion or load change possibility

Computer software like AutoCAD, Tekla Structures, and SAP2000 is typically used to analyze and model structural behavior before fabrication.

Future Evolution of Steel Truss Design

Steel structures made of steel will grow more sophisticated with the rising demands of construction. Some of the emerging trends are:

- Use of cold-formed steel in lightweight truss systems

- Solar panel mount system combinations

- Smarter coatings for fire protection and corrosion

- BIM (Building Information Modeling) for fully digital design-to-fabrication workflows

Continued evolution of triangular roof truss engineering will continue to push the boundaries of architectural and industrial design.

Conclusion

The triangular roof truss and the steel fabrications together constitute one of the most sustainable, scalable, and efficient offerings available in modern building design. For an industrial warehouse complex, an agricultural shed, or a giant commercial complex, this structural solution will be the best with the least wastage of material.

With the demand for faster, safer, and more eco-friendly buildings growing more urgent, developers and engineers will be heading more and more in the direction of steel framing that leverages the proven strength of the triangle.