Rock wool sandwich panels have become a bestseller in the building materials market in recent years. Behind this trend lies not only their superior performance,but also the environmental demand for energy conservation.

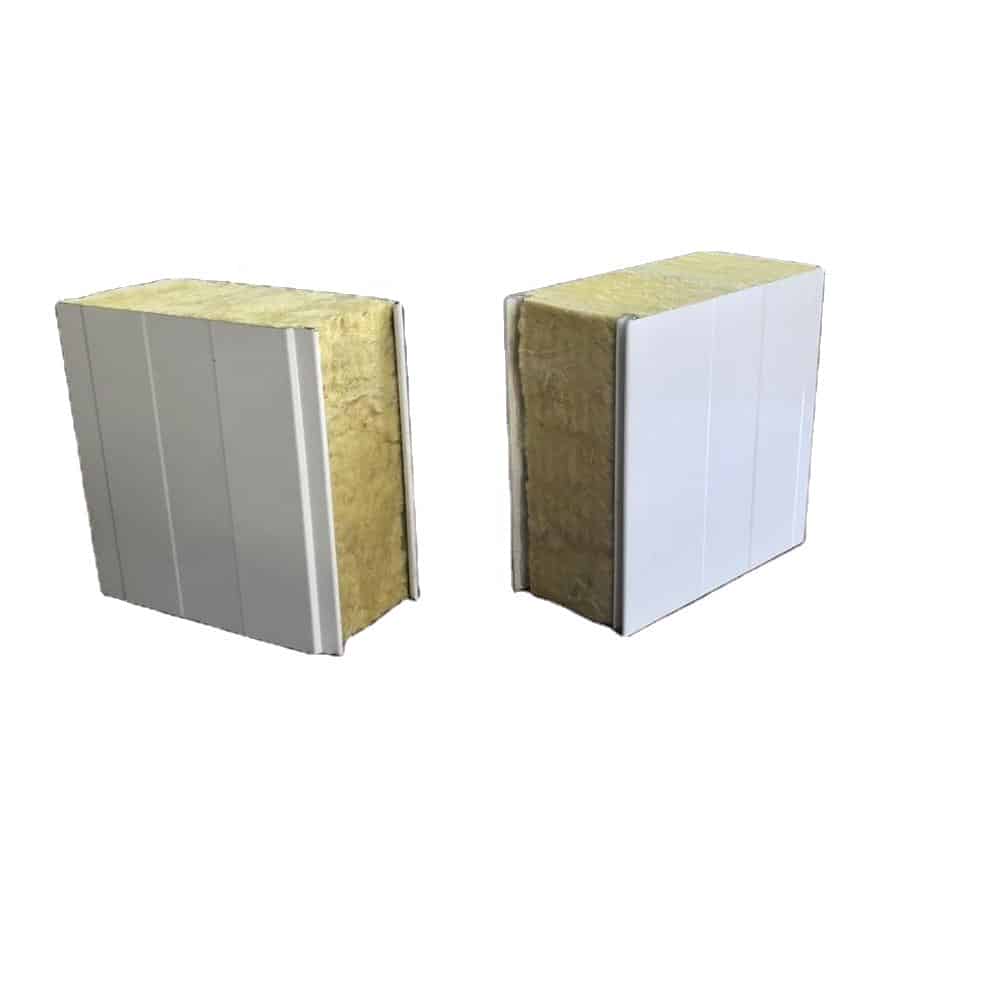

Rock wool sandwich panels are filled with inorganic fiber materials. This material, derived from natural basalt, not only possesses great plasticity, but also features properties such as water resistance, fire resistance, and non-corrosiveness. Additionally, the porous structure inside the rock wool endows it with excellent insulation and soundproofing capabilities.

After achieving mass production in the 1980s, rock wool sandwich panels quickly became a rising star in the construction industry. Buildings installed with rock wool sandwich panels enhance fire resistance and sound insulation. They can also effectively reduce the electricity consumption of air conditioning for residents. This aligns perfectly with the environmental and energy-saving demands of the times.

Furthermore, the emergence of rock wool wall panels provides designers with the opportunity to further beautify the appearance of buildings. By installing customized sandwich panels, buildings can exhibit more rich and beautiful exteriors.

Throughout this process, people have increasingly realized the importance of the flatness of rock wool panels. The higher the flatness, the better the fit between the rock wool panel and the building exterior, resulting in smaller gaps between the panels and better installation effects. This raises higher demands on the manufacturer of rock wool panels.

Firstly, manufacturer must select high-quality rock wool to ensure even fiber distribution and strong adhesion. Secondly, they need to choose high-quality colored steel plates to ensure that the flatness, coating thickness, and corrosion resistance of the panels meet standards.

In addition, compared to other panels, rock wool panels demand higher precision in the production line. Factories need to adopt advanced processes to ensure the integration of rock wool fibers and colored steel plates while minimizing the appearance of large pores. Furthermore, they must rely on precision processing technology for accurate cutting of the panels to eliminate dimensional deviations as much as possible. Only in this way can high-quality rock wool panels with better flatness be produced.

Harbin Dongan Building sheets Co., Ltd. has selected excellent equipment to establish a leading production line for rock wool panels. Leveraging the strong industrial production foundation in northeastern China, Dongan uses high-quality rock wool and colored steel plates. At the same time, Dongan continuously optimizes the structure and detailed design of rock wool panels, ensuring that the panels are more stable under stress and more durable. The modular installation design also allows Dongan’s rock wool sandwich panels to achieve a more flat and refined final effect. As a leader of building sheets in China, Dongan company will continue to provide better products and services.

Leave A Comment